Do you know the difference between high temperature cooking bags and vacuum bags

First, the concept and principle of high-temperature cooking bags and vacuum bags

High temperature cooking bag is a kind of plastic bag designed for high temperature cooking, usually made of polyester material, can be repeatedly cooked at high temperature without breaking, waterproof performance is good, is widely used in food factories and catering bags. The principle is to use special polyester materials at high temperatures, so that the bag does not deform, does not leak, and can maintain the nutrition and taste of the food after cooking.

Vacuum bags are bags that seal food in a vacuum environment and are often used for commercial and household food storage to maintain the freshness and nutrition of food. The principle is to eliminate the air after sealing by pumping, reduce the contact between food and air and achieve the effect of anti-oxidation and preservation.

Second, the use scenario and method of high temperature cooking bag and vacuum bag

High temperature cooking bags are used for food cooking, processing and packaging. Processing food at high temperatures can kill bacteria and ensure food safety and hygiene, and the use of high temperature cooking bags can ensure that food will not break during high temperature cooking, so as to achieve the purpose of sterilization. When using a high-temperature cooking bag, you need to choose the temperature according to the temperature level on the bag, and put the food into the bag, and then put it into the steamer for cooking.

Vacuum bags are often used for food preservation and storage, especially perishables and high-value foods. When using vacuum bag storage, you need to put the food in the bag, and through the vacuum machine to remove the air in the bag, and then seal it. In use, it is also necessary to pay attention to the material of the bag itself and the sealing performance of the bag to ensure the quality and safety of the food.

Tag:

Previous Page

Next Page

Previous Page:

Next page:

Recommend News

Yisu Plastics Company provides packaging materials and packaging solutions to customers

Paper plastic bag packaging materials sterile items storage time

Advantages and disadvantages of aseptic paper-plastic aluminum packaging

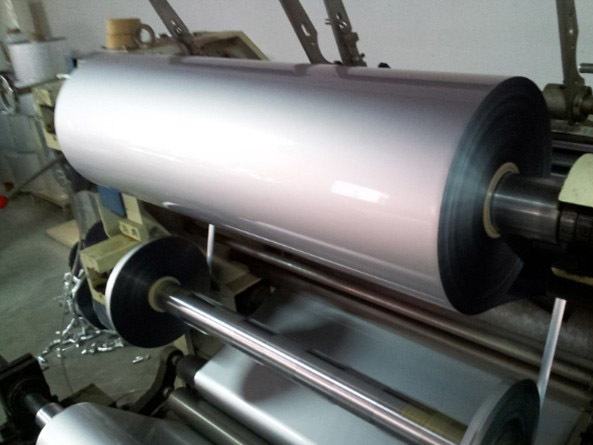

The production process of aluminum-plastic composite film is detailed